Solutions for your processes

Industry

From lab to production

We scale with you

Whether you are developing new formulations or producing at full industrial scale, IKA provides precision-engineered solutions for every step of your process.Read more

Knowledge Center

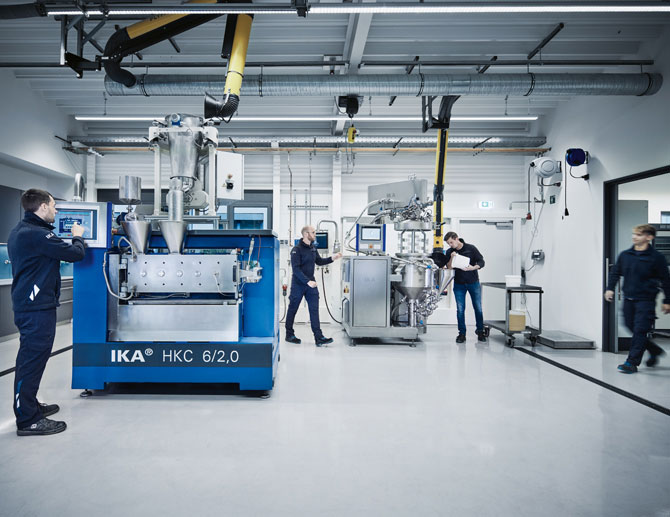

IKA Test Center

Searching for a suitable machine for your application? At IKA Test Center you can test several mixing systems with a variety of tools. Our process engineers look forward to assisting and advising you during and after the experiments. This way an optimal solution for your specific mixing task can be determined.

Read more

Download Center

In our Download Center, you will find a wide range of information materials on process technology. Whether you are looking for flyers and brochures about our machines and plants or specific white papers or success stories, browse through our download area and learn more about the world of IKA process technology.

Read more

Services

From the very start of your project IKA has been part of it and assists you during the planning stages through its realization by offering a multitude of services like designing entire production plants, performing test runs when developing new products, planning and implementing of mechanical, electrical, and pneumatic installations, commissioning and qualification.

Read more

IKA News & Working at IKA

Stay informed: Read our latest news here. In our news section, we keep you up to date on upcoming trade fair appearances, events at our branches, and product developments.

In addition, you can find all our videos in one place on our video channel.

Read more

Work at IKA

All employees help us move forward:

That's why so much revolves around them. Anyone who comes to IKA immediately notices the collegiality and the friendly and informal interaction. As a family business, we value and promote this special atmosphere. It is one of the foundations of our success.

Read more

Welcome to IKA

Originally a supplier for laboratories, pharmacies and hospitals, IKA quickly developed into a successful player on the international stage - both in laboratory and analytical technology and in process technology. In recent decades, the Process Technology division has developed into a leading manufacturer of mixing & drying technology. The Process Technology division of IKA offers turnkey solutions and state- of- the- art manufacturing options. IKA‘s solutions include: dispersing machines, homogenizers, stirrers, jet flow agitators, kneading machines, vacuum dryers as well as ready- for- use process plants, all being manufactured in IKA‘s outstanding high product quality. Consulting, design and realization of complex projects as well as proactive after- sales services complete IKA’s solution portfolio. Thanks to constant integration of innovative technologies, the high- quality machines and plants are used in many industries, such as the pharmaceutical, food, chemical, battery and bitumen sectors.